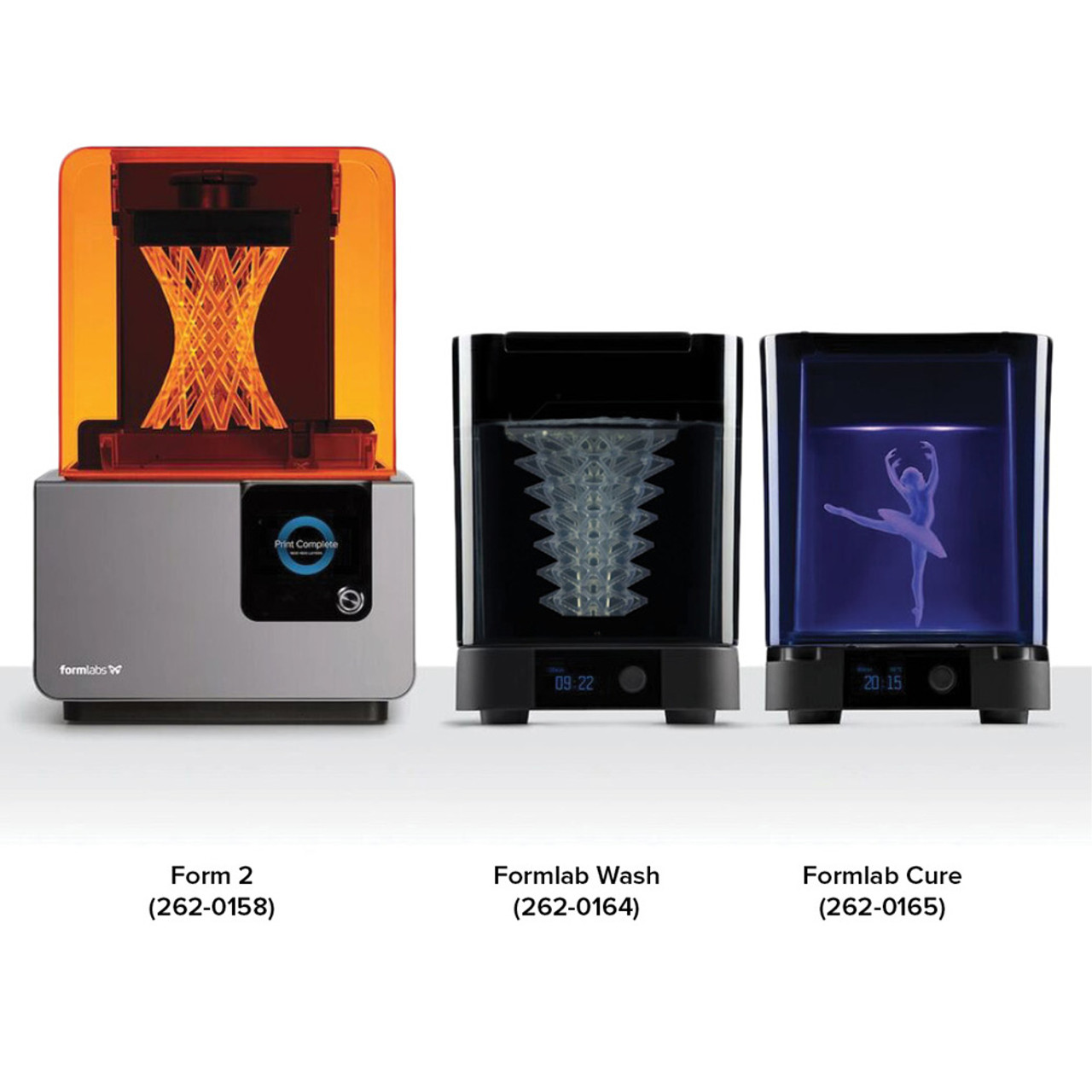

Once your parts are created in the FormLabs Desktop 3D Printers, they will require post curing. We recommend using the Form Wash which cleans the parts while still attached to the build platform. The impeller in the Form Wash agitates isopropyl alcohol (IPA) to flow around every nook and cranny of your part, getting them perfectly clean every time. When washing completes, Form Wash automatically raises parts out of IPA, making sure your designs never warp. Parts air dry and some resins will be ready for use and other require additional curing in the Form Cure (sold separately).

Parts travel straight from the FormLabs printers to Form Wash; they can stay right on the build platform or be removed and placed in the basket. Keeping delicate jewelry prints on the build platform during washing and drying protects fine details during post-processing. Printer compatibility: Form 3, Form 3+, Form 3L, Form 3B, Form 3B+, Form 3BL, Form 2

Form Wash can hold up to 8.6 liters (approx. 9 quarts) of IPA, enough to wash approximately 70 prints. The wash bucket is removable. An included hydrometer lets you know when it's time to change out IPA. A siphon pump makes it easy to transfer IPA into and out of the wash bucket. Approximate wash time when using fresh isopropyl alcohol is 15 minutes.

Electrical: 90~264V, 2amp, 50/60Hz. 1 year manufacturer's warranty. Made in China.