Sisma Laser Welders for Industrial

Sisma laser welders are a technological breakthrough in the world of mold and die repair. These heavy-duty laser welders are designed for industrial use to perform incredibly precise welds with fast results. Expand your repair shop and improve quality control.

Explore Our Laser Welders and Choose Your Ideal Model

-

SWA 150 & 300 Welders

Key Features

- Weld any mold size.

- Sisma's most flexible laser welder.

- Advanced fiber transport of laser beam.

- Programmable path settings - Overlap, Line, Radius, Oblique, Fill, Rotating Spindle

- Motorized control of X, Y, and Z Axis (via Joystick).

- Internet connection for Remote Service Management and free upgrades.

-

SWT Open & Closed Fiber Welders

Key Features

- Medium to small mold sizes.

- Ergonomic design for maximum user comfort.

- Programmable path settings - Overlap, Line, Radius, Oblique, Fill, Rotating Spindle

- Motorized control of X, Y, and Z Axis (via Joystick).

- Internet connection for Remote Service Management and free upgrades.

-

SWA 300 & 450 Fiber Welders

Key Features

- Fiber laser source

- Maintenance-free

- Increased production rate

- Advanced software functions

-

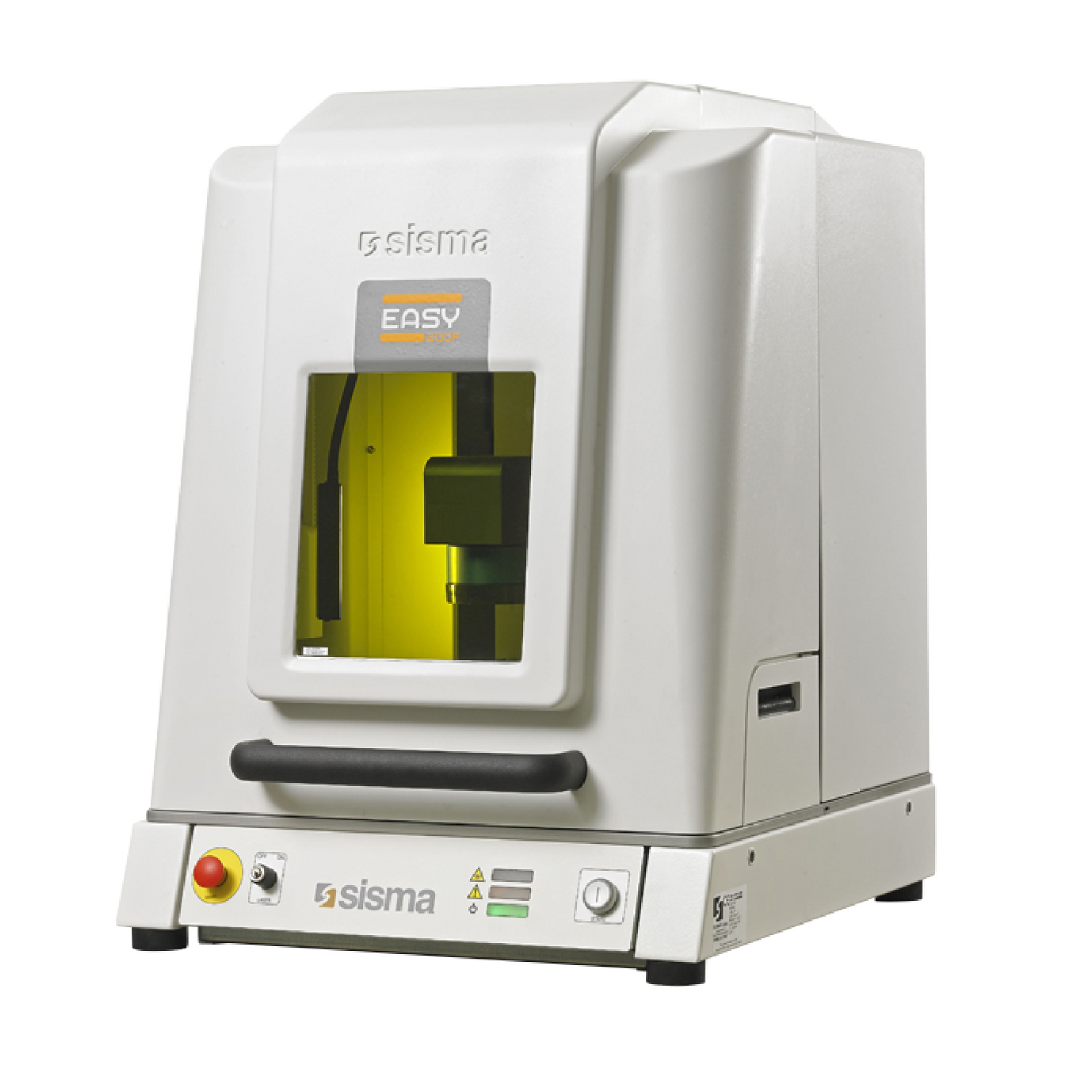

LM-B and LM-C Welders

Key Features

- Designed for small molds.

- Fast setting of Welding Parameters (via Keyboard)

- Motorized control of X, Y, and Z Axis (via Joystick).

- Internet connection for Remote Service Management and free upgrades.

Contact Us for More Information

Leasing

Leasing offers a way to quickly get what you need without tying up your cash and best of all, allows you to deduct the lease as a business operating expense. We work closely with a few reputable firms and will assist in making it as simple as possible.

Shop our Laser Engravers

Advance your business with Sisma's state-of-the-art fiber optic laser machinery

Customer Reviews

-

“The laser machine has come to add value to our mold maintenance process. I can say that the time and cost of repairs have decreased. The machine is more user-friendly so more technicians have learned to use it and we have extended our repair capabilities.”

Rudy Molina Porras | Molding Maintenance Manager, Panduit

-

“We have had the welder in house since January and since then we have not sent anything out to be welded. I have been able to keep up with the need of repairing tools for 100+ presses in production. This laser welder is so precise and yet I can add a big corner to something if needed. Another nice thing about the welder is the quality of the weld. I have yet to have something come back because of pitting or porosity.”

Todd Stegar | Hellerman Tyton

Service and Support

With our knowledge of the mold industry, we understand how critical it is to get your molds back into specification and in the press. Our team of service professionals are ready to give you the support you need. Whether it's helping you choose the right laser, providing training on your new laser, or servicing your existing Sisma laser- we've got you covered. The following services are available to customers who own a Sisma Laser from Gesswein.

-

Trained Laser Professionals

Our team of account managers and service technicians are fully trained on our laser systems so we can give you the best quality service.

-

Laser Install + Training

Our experts will both help set up your machine and teach you how to maintain it, so you can keep your machine running smooth for years to come.

-

Preventative Maintenance

All machines need adjusting every now and then. Should your machine need repair or a replacement part, we are standing by to get you what you need, fast.

-

Remote & Onsite Support

Should you have any questions about your machine’s performance or need help troubleshooting, our experienced technicians are available for remote or in person consultations.

Meet Our Experts

-

Michael Dawes

Industrial Sales

-

475.445.5977

mdawes@gesswein.com

-

Pete Jaisaree

Industrial Sales

-

475.445.5979

pjaisaree@gesswein.com

-

Lenny Provenzano III

Industrial Service Technician

-

475.445.5976

lprovenzano@gesswein.com