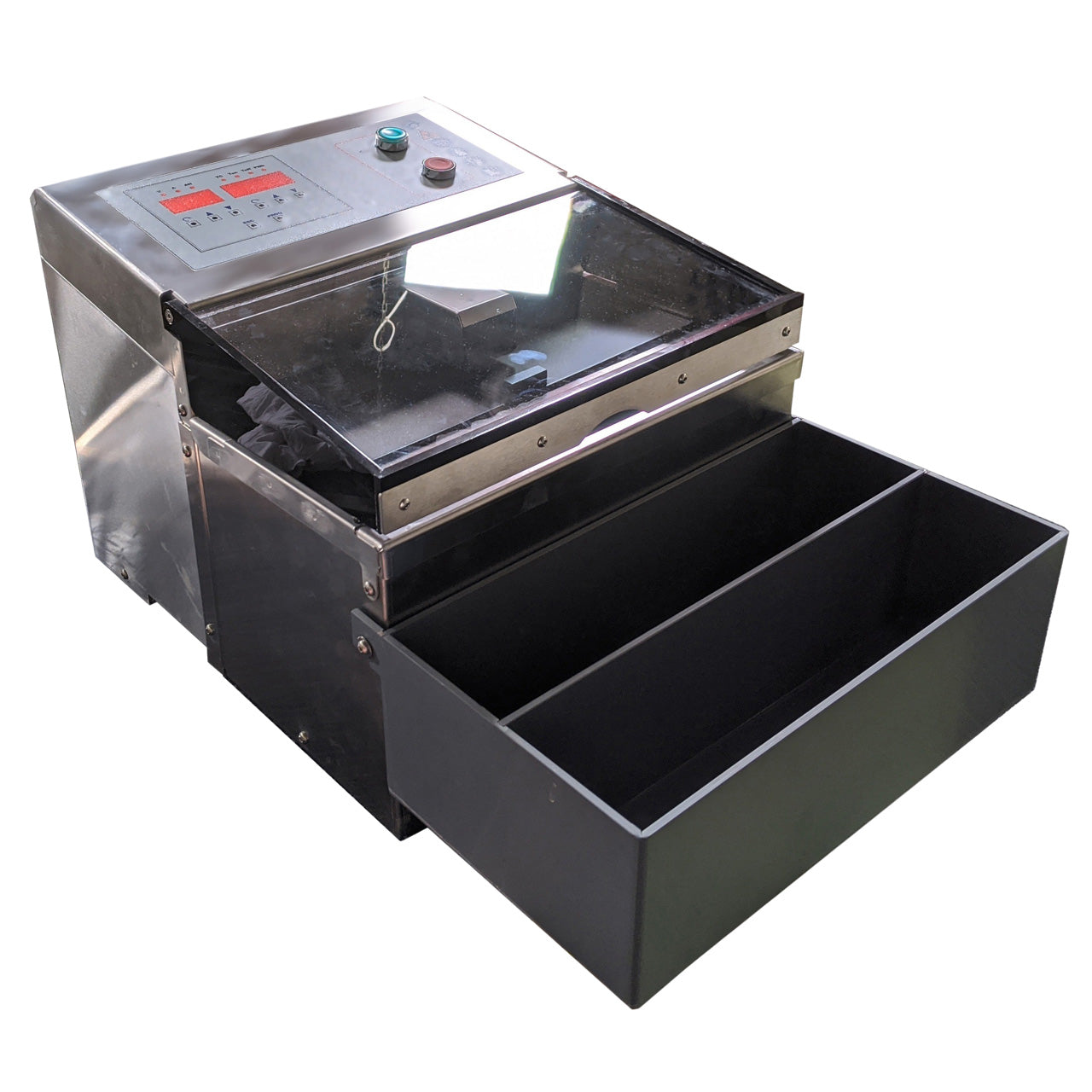

Hispana EN-34 2nd Step Electro Polisher

Hispana EN-34 2nd Step Electro Polisher

Product Specifications

Product Specifications

Safety, Compliance & Product Documentation

Safety, Compliance & Product Documentation

Product Description

The EN-34 model is designed for jewelry companies that carry out a small production, but require high quality finishes.

This machine can process 9 - 21 pieces simultaneously in one to two hours, depending on the density of each piece.

The EN-34 can also work with gold in 9 karat up to 22 karat and in different colors, such as white, red and yellow, as well as silver and brass, all by simply changing the electrolyte. This makes it a very versatile solution for small jewelry companies. We suggest considering our SP211 (8522010) if you work only with silver.

This model is based on the Second Step Energy system that uses small particles of up to 0.3mm in diameter as a catalyst for the chemical process, pushing against the pieces with an exclusive energy system, thus giving the system its name “EN”. Our EN-34 can hold 12kg (approx. 26lbs) of product.

Includes a simple controller, keypad and two screens allowing the operator to save specific parameter settings for each alloy, saving time and creating consistency. Made in Spain.

Why is Electropolishing effective?

- Decrease your polishing time significantly

- Decrease the amount of metal removed during the process

- Increase your quality, while decreasing your overall productions costs in comparison to manual hand polishing labor