ENESKApostprocess

Grind, Polish, and Finish 3D Metal Printed Metal Support Structures Safely and Efficiently with ENESKApostprocess, a Revolutionary 3D Post-processing Vacuum-Sealed work station.

3D Post-Processing

Our fully enclosed post-processing stations offer enhanced protection, powerful suction, and support...

Safety and Versatility

-

Workforce Health

Enclosed workstation protects your technicians from inhaling toxic metal powders.

-

Minimal Explosion Risk

Completely earthed design prevents sparks from reactive chemicals.

-

Full Functionality

Large working platform accommodates support removal and grinding tasks.

-

Advanced Filtration

Vacuum sealed chamber collects metal powders (99.95% filtration efficiency).

Contact Us to Request a Demo

Optimal Ergonomic Working Space

The adjustable height platform, dimmable lighting, and large glass dome provide optimal and ergonomic working conditions, while the large working platform (50"W x 60"D x 70"H) accommodates various fixtures such as turntables, magnetic clamping balls, and other vices, allowing secure support for both simple and complex geometries.

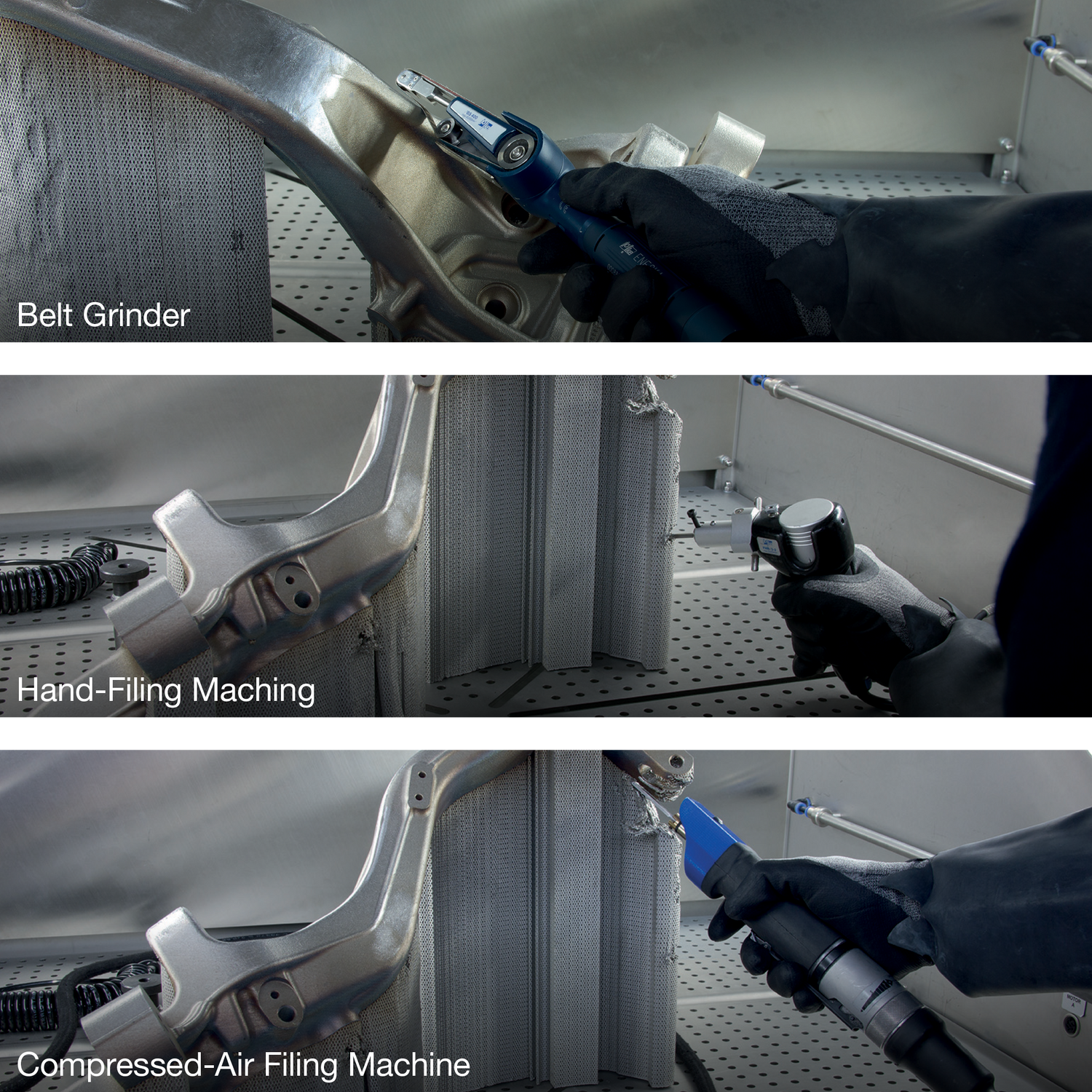

Grinding and Finishing

The Eneskapostprocess powers a variety of electrical and air tools to perform various post-processing tasks such as support and substrate removal, grinding, deburring, and polishing.

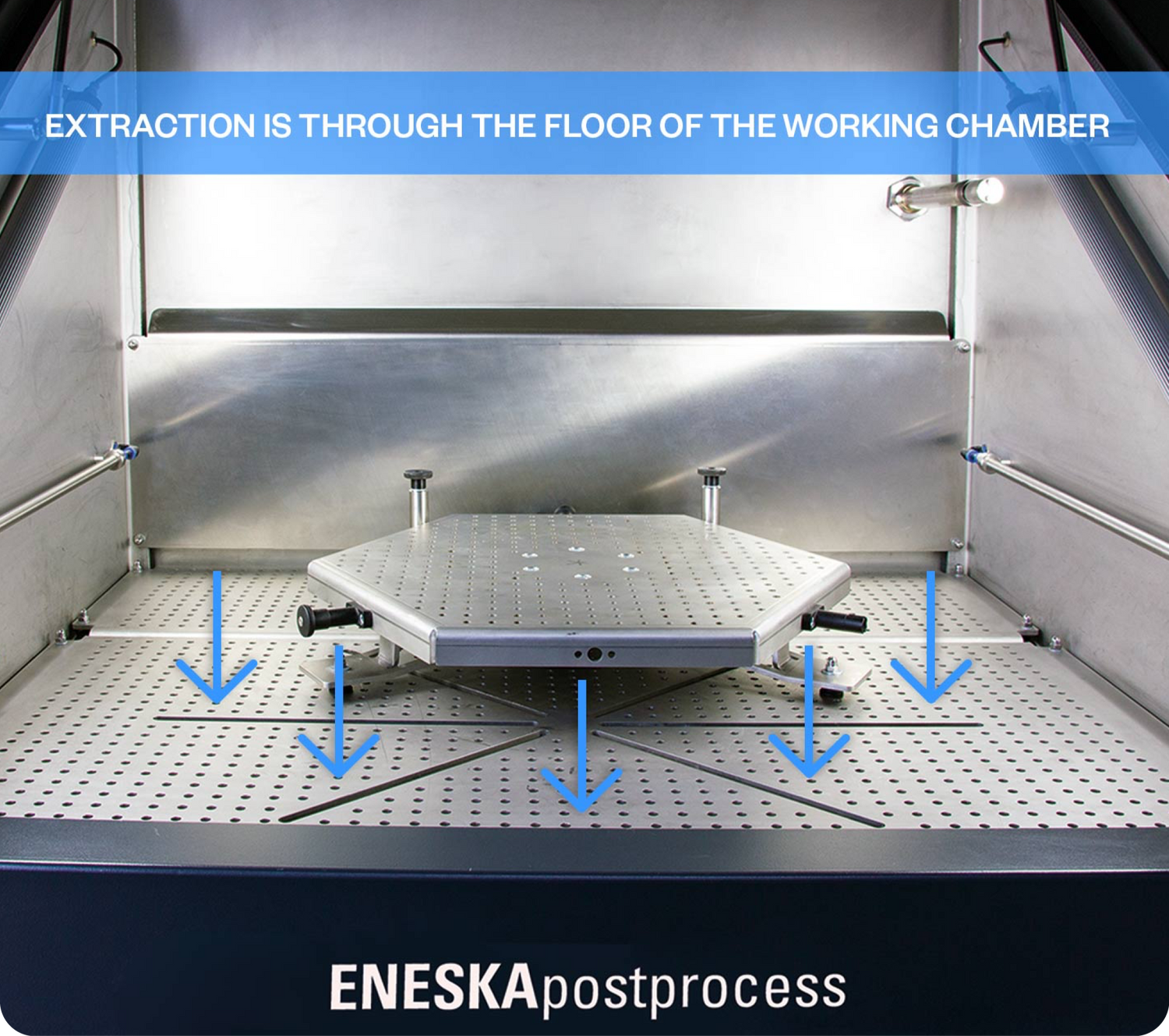

Advanced Filtration

A combination of compressed air jets and vacuum suction directs hazardous powders to the 5-stage filtration system. Inert oil is required for safely capturing reactive powders such as titanium and aluminum.